The aluminum framing process is a process that is the result of aluminum extrusion, where aluminum is heated and then reformed to create frames. It is a growing market, as aluminum frames and products of aluminum extrusion are used in many manufacturing and engineering fields today.

More and more industries are turning to aluminum framing for their mechanical applications, as it is lightweight, energy-efficient, and in many cases more durable than steel. In 2019, the aluminum extrusion market was valued at $77.8 billion, with a projection of $118.7 billion by 2027. Learn more about the steps in the aluminum framing process here.

Benefits of Aluminum Framing

Aluminum is regaining popularity today due to its malleability, and that it can be reformed into a number of products for use on items such as bridges and vehicles. As both raw material and the recreated product, it has a high energy absorption. When it is extruded, it can take on a number of shapes and assembly patterns.

The Process of Aluminum Framing

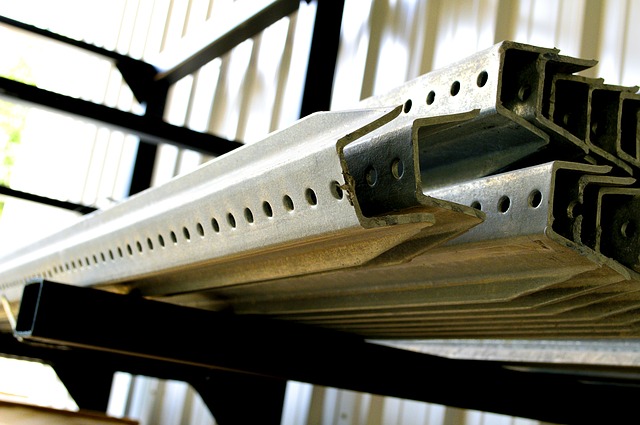

Aluminum extrusion is the process of working with aluminum to create a tube or frame through extrusion. In this process, aluminum is pushed through a die to create a lengthy shape. The die itself has a specified profile. The process can be compared to a tube of toothpaste. When you push toothpaste through a tube, it comes out, or extrudes, in the exact same shape as the toothpaste.

The extrusions are then used to construct aluminum frames. The shapes that are extruded can be solid, hollow, or be a little of both.

Once the extrusion is finished, the extrusions are then heat treated. The heat-treating process will prepare the aluminum for a surface finish. The purpose of the surface finish is to protect against corrosion, and also for aesthetics. Many aluminum framing manufacturers like Mini Tec Aluminum Framing will offer aluminum framing in a variety of colors.

Additional fabrication can transform the frames into a finished product with the desired dimensions of the customer. You can also ask for them to be drilled or machined according to your specific design.

Design Your Aluminum Frames Today

The aluminum framing process begins with the aluminum extrusion process. In this process, aluminum is heated and then pushed through a die. From this, frames that are either hollow, solid, or partially both are designed. These frames are now part of a multi-billion-dollar industry that is, among other things, serving as infrastructure for bridges, and framing more energy-efficient vehicles. Contact an aluminum framing professional near you to design your own aluminum frames today.

Leave a Reply